5 Benefits of Buying American-Made Label Printing Equipment

Label producers of all sizes—from small businesses to large label makers—recognize the value of in-house label production.

From reducing per-label costs to granting superior control over the small-batch label production process, in-house label production offers significant benefits over buying pre-printed or pre-die cut labels, especially for short-run or custom label production.

However, not all label production equipment is the same when it comes to who is delivering the digital label printer and finishers, who is supporting you as you adjust your production line, and who is training your staff to use the equipment in the best way possible.

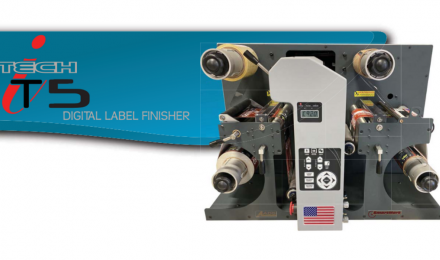

Here at Allen Datagraph Systems, Inc., we proudly manufacture our digital label equipment right here in the United States, and our expert staff is able to provide top-notch service and support to producers across North America from our headquarters in New Hampshire.That offers our customers significant benefits—benefits you just can’t get when working with equipment providers located overseas.

Here’s a look at five of the biggest benefits to choosing American-made label production equipment for your label production process, and why buying American might just be the best option for your business.

1. White-glove support for quick installation, training, and service

Label producers who know the value of short-run label production know that rapid, reliable service and support are critical to keeping the printing and finishing process moving in the face of unplanned setbacks.

However, for businesses relying on overseas label equipment manufacturers, the time it takes to access that service can often be days or weeks after the problem is reported. That time delay can end up costing hundreds to thousands of dollars in lost productivity if not addressed quickly and efficiently.

That’s because many small businesses and label producers—even those already well-familiar with the label production process—still benefit from reliability and consistency in the service and support process. Having the same individual who helped with initial setup and training also available to step in when a problem arises can be enormously beneficial, and might make the difference between a quick, rapid response and a slow, costly one. When there’s an ocean to cross to get support, that response time can become significantly slower… and that could mean lost revenue for your label production business.

2. Easy to access parts, repairs, and materials as needed

Even for the most skilled label producers and printers, there is one aspect of working with an equipment manufacturer that often becomes a critical piece of the relationship: access to parts, repairs, and materials for your digital label printer or finisher.

Whether you’re interested in trying a new type of label material, you’re in need of a replacement part for your machine, or your equipment needs a more intensive repair after encountering a production issue, having a trusted and accessible manufacturer to rely on may be necessary to keep your short-run label production process moving smoothly.

To put it another way: when your label finisher or printer suffers from a malfunction that requires professional assistance from the manufacturer, having that professional available quickly could be the difference between getting back up and running in short order, or losing out on valuable productive time.

3. Quick turnaround from point of order to delivery

When it comes to investing in in-house label production equipment, it’s critical to consider the purchase decision from all angles. That will likely include factors like long-term value over the life of the equipment, the timeframe for ROI after purchase, and the ability to scale production to meet changing demand and capabilities.

One factor often overlooked, however, is the waiting time required after purchasing your label equipment itself. All too often, label producers are left waiting for days or even weeks at a time between the point of sale and the actual point of delivery.

This is especially true for label producers who choose to work with equipment manufacturers based outside the United States. Time and time again, we hear from label producers about the time delay between purchasing label equipment—after putting down money with the expectation of getting up and running quickly—and actually getting the equipment delivered, set up, and ready to print.

For label makers who count on quick turnaround and who are bound by tight margins on short runs of label production, this time delay is simply not acceptable.

That’s why our professionals at ADSI are proud to offer quick turnaround times for our customers, and why we specialize in putting our equipment into the hands of label producers within days of purchase. We recognize our customers’ need for speed and professionalism, and our proximity as a U.S.-based equipment producer allows us to deliver on time and within our customers’ required timeframes for ROI.

4. The personal touch of working with experienced local professionals

Things change quickly in the world of label production—trends come and go, new materials and styles take precedence, and demand for short runs of labels can rise and fall with the markets. For label producers trying to keep up and keep on top of the next wave, a local partner familiar with the industry can be a critical resource.

We know because we specialize in helping small-scale label producers access the tools, materials, and equipment they need to stay ahead, even in the face of a fast-moving industry.

For instance: cannabis producers operating in the newly-emergent cannabis industry here in the U.S. may face a variety of labeling and compliance requirements. At the same time, emerging competition in the market has made distinctiveness and uniqueness key to the creation of cannabis labels. For label makers who do not have a trusted local partner to rely on, keeping on top of these trends can be difficult… and access the materials and equipment needed can be even tougher.

At ADSI, we work hard to keep a close watch on what’s working for label producers right here in the U.S., and we adjust our offerings to best match the emerging needs of our customers. Whether it’s providing support for new processes or providing an easy way to acquire materials, this personal touch, and local experience can offer our customers a major leg up compared to those label producers who rely on overseas professionals for the same purpose.

5. Proven ROI of in-house label production equipment

As many label producers now know, in-house label production brings unique benefits that other production methods—including outsourcing label production, or simply ordering pre-die cut labels to print on later—just can’t match.

Short-run label production gives label makers the ability to produce small batches of custom, unique, and high-quality labels, which allows these smaller label producers to achieve a significantly greater ROI on their label production equipment in a relatively short time.

By working with our U.S.-based team at ADSI, our customers have been able to achieve this proven ROI without the hassle or time expense often required by overseas-based label equipment manufacturers. Because we are based right here in the United States, we can help our customers achieve these higher margins and lower costs in significantly less time, preventing loss due to unproductive waiting time and maximizing revenue for our customers from the day of installation.

Why Wait For Overseas Service? Choose American-Made and Get Down To Business Faster

Whether you’re looking to upgrade your existing label production process or you’re just getting started with short-run or small-scale label production, accessing the machines, materials, and support needed is a critical step to getting your label production up to speed.

Working with a locally-based equipment manufacturer may be the key to making that happen in a time that works for your bottom line.

If you’re ready to bring your label production process in-house and start achieving a greater ROI on your label production equipment, ADSI is best positioned to help. We’ve been helping label makers and businesses bring their short-run and commercial label production processes in-house for years, and we’re conveniently headquartered right here in the United States to help our customers get up and running to match the demands of the industry quickly.

Get in touch with our team for more information on our wide variety of capable digital label printers, finishers, and materials, and learn how working with a U.S.-based equipment manufacturer can provide real, immediate value to your label production process.